Sustainable materials: towards low-carbon building processes

“More than 4 billion tonnes of cement are produced every year, accounting for 8% of global CO2 emissions”

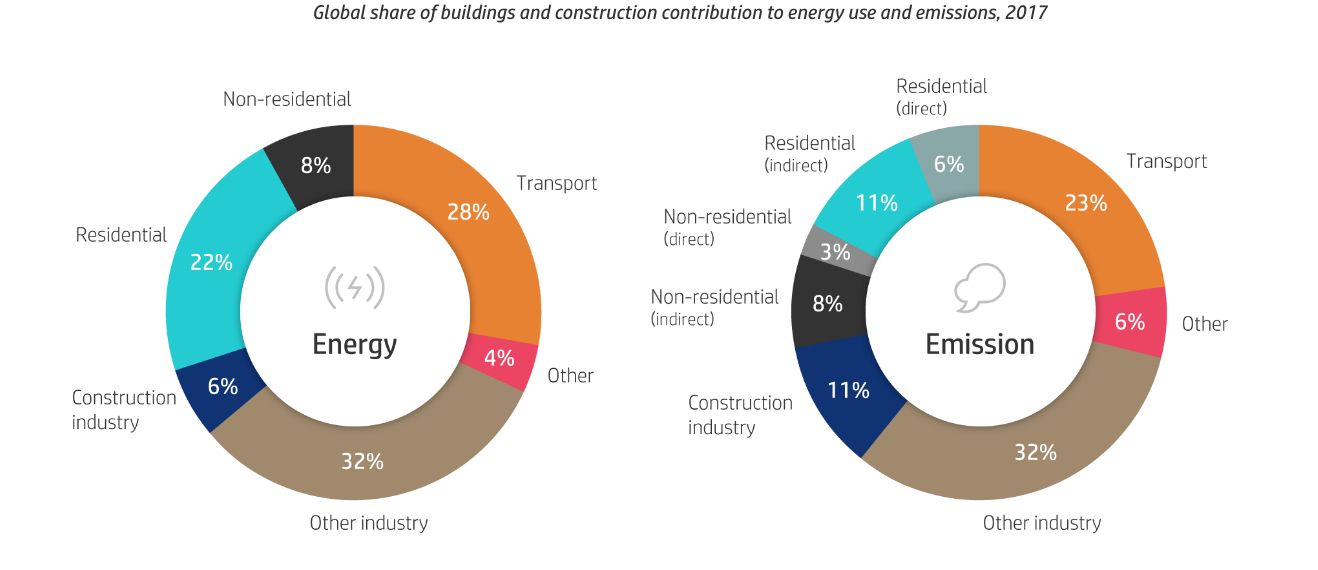

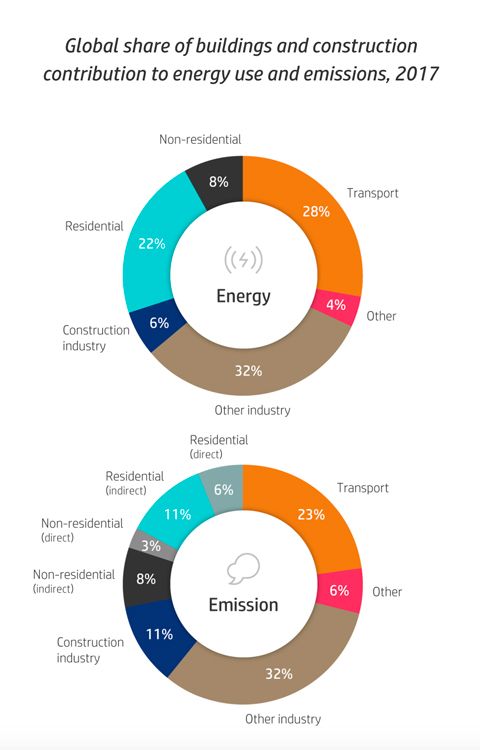

Building materials account for 28% of total buildings‐related CO2 emissions annually. Among the higher emitters are cement and steel - both emit high amounts of CO2 in the manufacturing process and are used in large quantities in most structures. Following close behind are aluminium, glass and insulation materials.

While cement and steel remain popular materials due to their strength, there has been growing interest in bio-based materials such as pre-fabricated cross-laminated timber (CLT) and bamboo. Rising prices of steel, together with increasing public backlash over the use of cheap, informal labour, has given further impetus for the AEC sector to deploy these new materials at pace.

Both International House Sydney and 25 King Street (Brisbane) were built with CLT, a material which has comparable strength to reinforced concrete. Developers say that the benefits of pre-fabricated CLT panels are threefold. It enables quicker construction using less labour, has about a quarter of the carbon footprint produced by conventional materials and adds to the biophilic nature of the building.

Bamboo is also making a comeback in construction after falling by the wayside due to a perceived lack of durability and strength. Essentially a hardy grass, bamboo grows fast, taking only 3-5 years to reach maturity, and does not need to be replanted after harvesting. It sequesters carbon at a rate higher than any other plant on earth except seaweed. As a construction material, bamboo is lightweight, flexible and strong. It also creates a char layer when exposed to fire, effectively serving as fire insulation.

At HP we’re committed to helping AEC professionals stay quick,

flexible and resource-efficient with the best tools to meet

tomorrow’s workflow challenges.

Sustainable design: more energy-efficient buildings

“Energy use for ‘space cooling’ increased by 25% since 2010. There are now more than 1.6 billion air conditioning units in buildings globally. ”

Air conditioning is responsible for more than 15% of global electricity demand growth. It is also responsible for 15% of the average global peak electricity load. This figure goes up as high as 50% on hot days in cities due to the urban heat island (UHI) effect. In keeping ourselves cool on amidst the growing heat we are ironically contributing to global warming.

Architects have begun incorporating passive cooling measures within building designs. One growing trend is creating “green” building facades with plants. This could reduce temperatures by 2-2.5ºC without air conditioning. While popular in Singapore and New York, vertical landscaping and rooftop gardens have yet to make an impact in Australia due to planning restrictions. Rooftop gardens are considered an additional storey to the building, which makes it difficult for developers to comply with acceptable rules for building heights.

Other elements of passive design include provision of daylight to reduce the need for artificial lighting, incorporating solar power, providing natural cooling ventilation, as well as minimising energy demand for air conditioning through insulation, windows and air tightness.

Smart technologies: digital transformation for sustainability

“Processing power per dollar will increase a billion-fold within 30 years”

Smart cities are the future of the developed world. From data centres, citywide wifi, and IoT (internet-of-things) solutions such as smart lighting and energy management systems, city planners will be increasingly reliant on next-generation infrastructure to meet sustainability goals. AEC companies looking to play a role in that glimmering future must adapt to technological advances or be left behind.

7D BIM technology is already available. With it, builders can incorporate environmental impact data into the model at the early design stage of construction, creating more precise simulations in later stages of the project cycle. This enables energy savings to be planned and targeted with more accuracy, reducing the gap between predicted and actual building performance.

Designers, for example, could select building materials based on quantifiable data as well as aesthetic. Information on the materials’ level of recyclability and resulting carbon footprint when demolished are some metrics that could be considered. This reduces both the embedded energy content of the building and makes the entire structure more sustainable as the materials could be reused or recycled.

Some AEC companies have begun integrating digital technologies at the workflow level. Cloud-based collaboration solutions and 24/7 connectivity have led to productivity gains through a reduction in missteps, miscalculations and ultimately less wastage in the field. Digital transformation is never an easy process, but technology partners that place priority on sustainability, in addition to productivity, will help make the shift easier.

Sustainability is here to stay. It is now up to AEC companies to adapt to the more eco-conscious global citizens of tomorrow.

HP Large Format believes in sustainable product development and closed-loop recycling. Shape Australia’s

landscape with a technology partner that takes climate change seriously.